In the coming years, the construction industry will undergo serious disruption. The advancement of artificial intelligence (AI), machine learning (ML) and robotics will soon provide solutions to the industry’s greatest challenges – overcoming cost/schedule overruns, risk mitigation and boosting productivity.

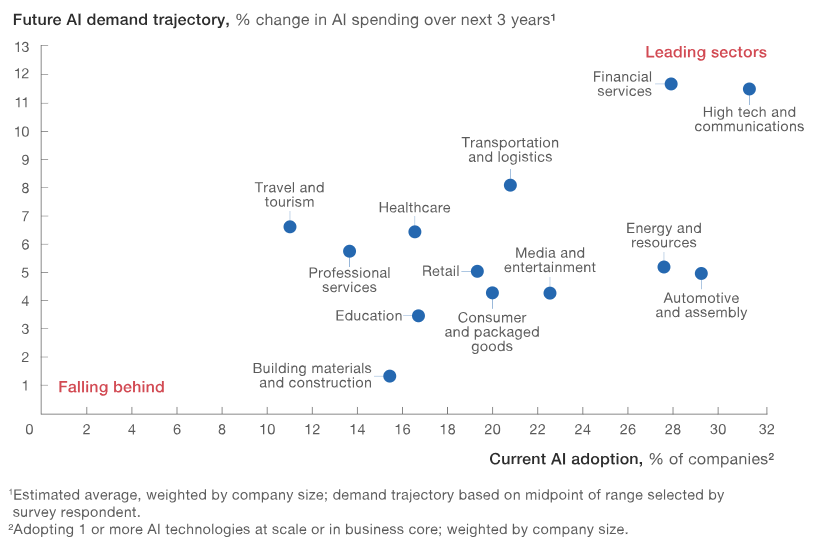

While many industries – like financial services and telecommunications – have embraced AI, the construction industry has been slow to adapt. McKinsey compared the construction industries to twelve other industries such as tourism, health and automotive and assemble and found that ten of them were ahead in the implementation of AI.

There’s plenty of room for improvement and first movers will set the direction of the industry and reap the benefits of artificial intelligence.

Preventing cost overruns

A recent IBM study found that AI has already proven beneficial within retail and consumer products for demand forecasting, supply chain planning and production planning. To help reduce costs, logistical burdens and manage cash flow, the same AI practices can be used in the construction industry to enhance supply chain coordination for materials and inventory management.

For this to happen, a significant investment is required in the digitization of the construction workflow. In the past, blueprints and drawings were used to express information about a particular building plan but many companies are adopting a Building Information Modeling (BIM) approach, and this market is expected to reach 4210 million USD by the end of 2024.

Not only does the BIM approach allow multiple stakeholders (i.e. architectures, engineers, project managers) to collaborate within a single 3D digital model, the collected data can be used by AI to make decisions before and after a building is constructed for use in future projects.

McKinsey estimates that construction projects currently lose up to one-third of their value to waste.

Constant real-time analysis by AI will forecast issues before they occur, and automate how materials and workers are distributed on a worksite to prevent cost overruns. McKinsey estimates that construction projects currently lose up to one-third of their value to waste. By using AI and machine learning to prevent cost overruns, construction companies will operate leaner, reduce delays and forecast problems and challenges for future projects.

Risk Mitigation

Artificial intelligence and machine learning are fast becoming an assistive tool to proactively identify risks and help stakeholders make decisions before it impacts their projects. AI supported cameras can continuously monitor all areas around a job site and allow project engineers and superintendents to analyze activities in real time when issues are detected. AI can use the camera data to assess equipment use, truck arrivals/departures and worker presence on-site at any given time.

As more and more data is captured and analyzed, AI-supported cameras can track progress and alert users about potential bottlenecks or delays before they occur.

The leading causes of death are known as the “Fatal Four” and account for 59 percent of deaths in private sector sites.

Health and safety issues within the construction industry can also benefit from the use of AI. Workplace injuries and fatalities on construction sites remain an ongoing issue occurring at alarming rates. The U.S Department of Labor reported that in 2017 one in five worker deaths were in construction.

AI has already proven effective in helping construction workers perform tasks safely. Research conducted at the University of Waterloo found that motion sensor suites and AI software helped expert bricklayers learn new techniques to limit the loads on their joints while working faster than colleagues with less experience. With the help of AI, bricklayers learned to maximize their output while minimizing the wear and tear on their bodies.

Boosting Productivity

Despite advancements in computer-aided designs, fabrication and project management software, the construction industry remains highly inefficient. Large construction projects routinely come in over budget and behind schedule. On the job site, the challenge for project managers is digitizing how much work on a job site occurs daily, and if that work was of high quality.

A new AI company Doxel uses drones equipped with LIDAR and HD cameras on job sites both indoors and outdoors. It applies deep learning algorithms to recognise objects, assess the quality of installed work and quantify how much material has been used. A cloud-based dashboard then provides project managers real-time feedback on productivity, and actual costs and time spent when compared to the original budget and schedule.

Out of all emerging industrial technologies, AI and machine learning will impact the sector the most by mitigating cost/schedule overruns, preventing health and safety issues and boosting the productivity on job sites.

Recent Comments